At HARBEC, as an ISO 13485 certified partner in the thriving Medical market, our commitment to your success drives our continuous improvement. We invest in top-notch processes, technologies, and skilled teams to provide you with the highest value.

Medical

Our Capabilities

Our facility boasts ISO 13485 certification in Plastic Injection Molding, CNC Machining, and Metal Additive Manufacturing, underscoring our commitment to excellence in the Medical market. This prestigious certification reflects our dedication to maintaining the highest standards in our partnerships. Our ongoing investments in advanced processes, technologies, and equipment, coupled with our skilled team, are focused on your satisfaction and success. These strategic enhancements in quality and operations are tailored to meet your needs, reinforcing our pledge to deliver exceptional value in every aspect of our collaboration.

The medical industry uses injection molding to manufacture a wide variety of products, which offers numerous advantages. Injection molding of medical-grade plastics is used to produce medical devices, components, laboratory and facility equipment, and more. A key advantage of injection molding lies in its ability to meet the exacting specifications and regulatory requirements of the medical industry.

Lateral Flow Assay Cassette Mold

Explore HARBEC’s agile approach in our detailed case study, illustrating our ability to adapt to evolving design requirements while meeting fast-paced production demands. Download the case study to see how we effectively produce high-quality parts within tight timeframes and collaborate closely with customers to ensure successful outcomes, even when prototyping time is limited.

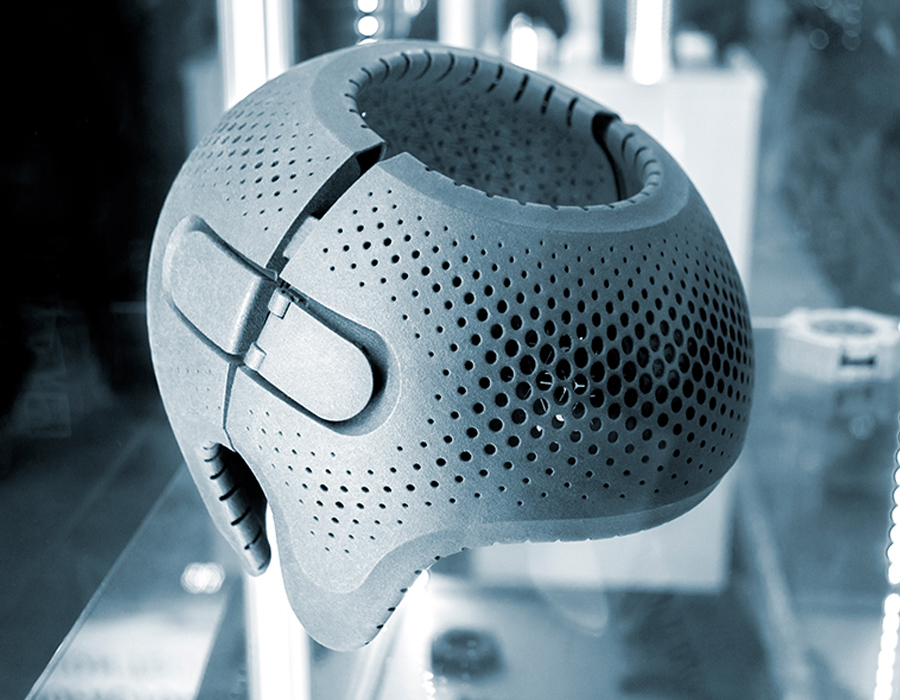

HARBEC has developed expertise in both metal and polymer printing technologies.

METAL:

We use cutting-edge metal printing technology to produce surgical tools that are both durable and precise, ensuring that they can withstand even the most rigorous medical procedures.

POLYMER:

With our polymer printing technology, we are able to produce accurate and detailed digital anatomy models that can be used for medical research and training purposes. By utilizing the latest 3D printing technologies, our team at HARBEC is able to offer innovative solutions that can help advance the field of medicine and improve patient outcomes.

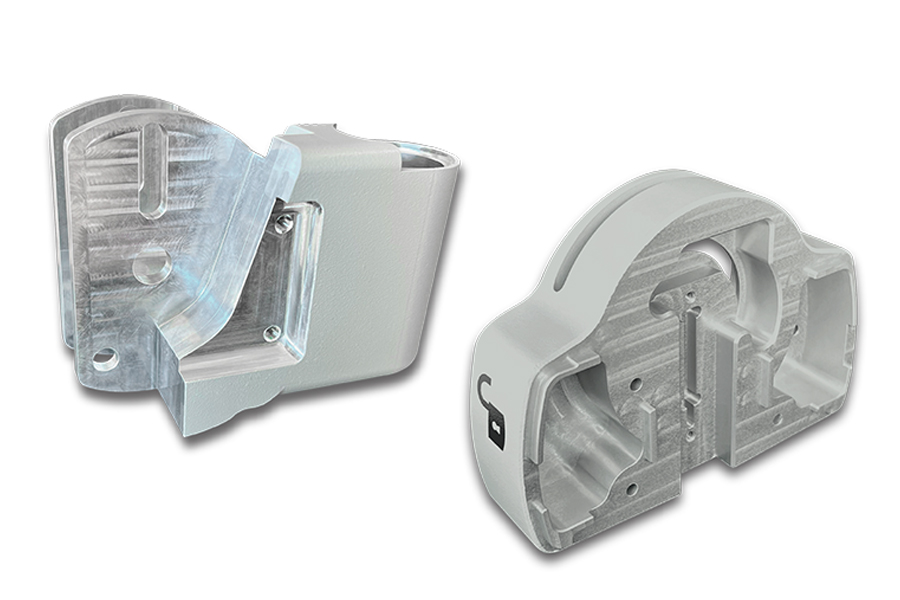

CNC machining empowers the fabrication of intricate internal configurations within medical devices, a crucial capability for implants and devices with specific needs like channels, cavities, or complex fluid pathways, as seen in drug delivery systems or microfluidic devices. Utilizing CNC machines with multi-axis capabilities, we can accurately carve out these internal structures from a wide range of materials, guaranteeing the medical device’s optimal functionality and performance.

Technologies for Medical Device Manufacturing

In this in-depth eBook, we will explore the diverse technology portfolio of ADDMAN and its comprehensive ability to support medical applications across various fields. From Polymer 3D Printing to Metal Additive Manufacturing, Injection Molding to CNC Machining, we will delve into the remarkable capabilities and advancements that are revolutionizing medical manufacturing.